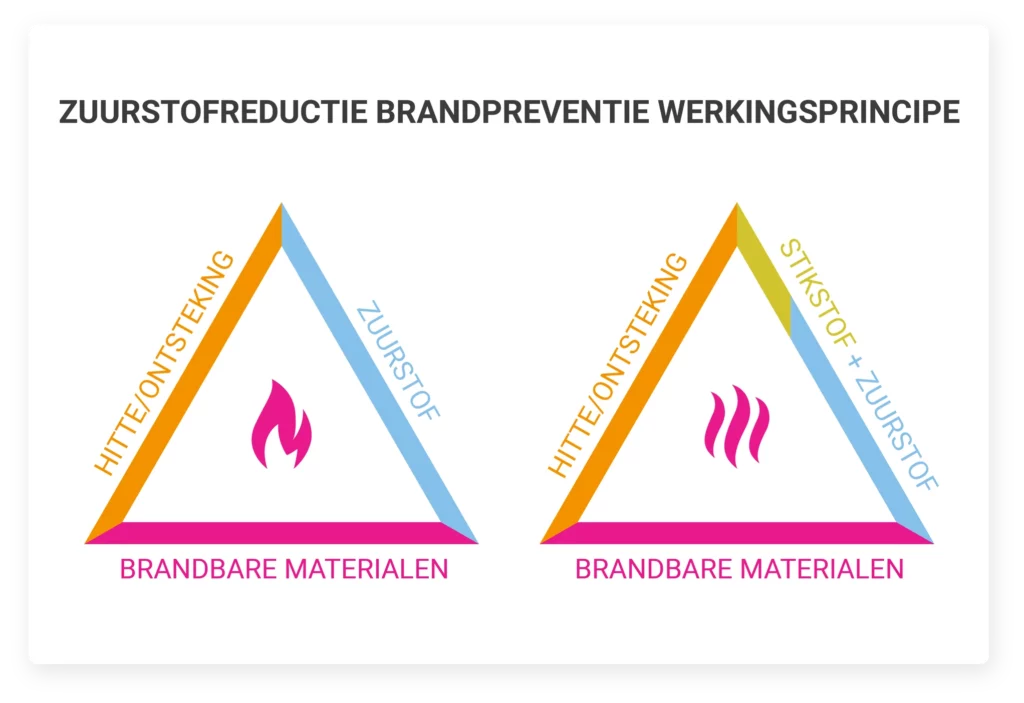

Operating principles of oxygen reduction fire prevention systems

Operating principles

The benefits of preventing fire, rather than extinguishing it, make oxygen reduction systems well suited for applications where fire can cause irreplaceable damage and where traditional fire suppression systems are unacceptable or unsuitable.

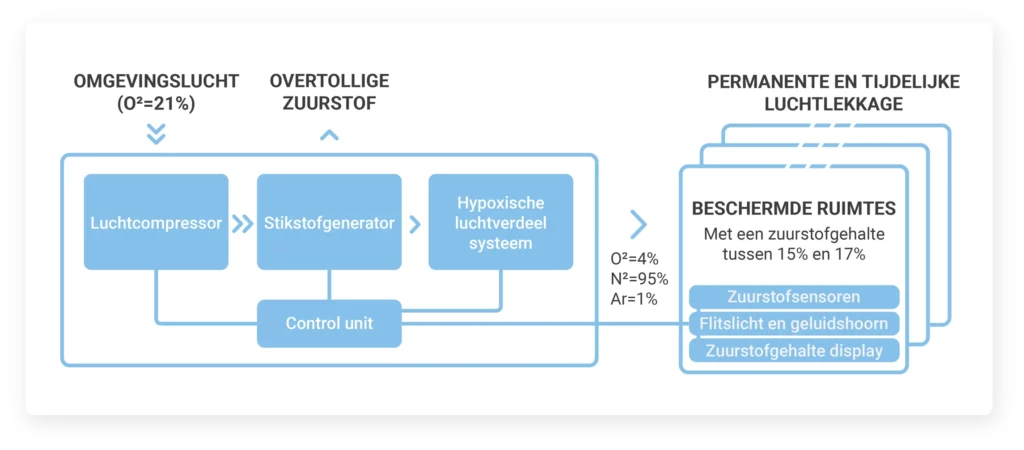

Hypoxic air technology for fire prevention, also known as an oxygen reduction system (Presscon FX Prevent systems, LOX Low Oxygen Systems), is a proactive fire protection technique based on permanent reduction of oxygen levels in protected areas. The technology of lowering oxygen by administering nitrogen has been used in various industries for decades.

We have more than 20 years of experience in various methods of controlling oxygen and nitrogen concentrations in the air, using nitrogen generators. The agriculture and horticulture industry uses the principles of this technology to preserve goods. The petrochemical industry uses it to create a nitrogen blanket on combustible materials(blanketing). In that capacity, this technology has proven to be very successful and reliable. The most popular methods in this industry use a membrane filter or a (V)PSA filter, which stands for “(Vacuum) Pressure Swing Adsorption.”

High Performance PSA (HP-PSA).

With the use of PSA (Pressure Swing Adsorption) technology, Presscon FX Prevent has developed a completely new (HP – High Performance) system that eliminates the disadvantages experienced with a traditional PSA system. HP technology distinguishes itself through an optimized air flow in the system and a unique pressure system for the activated carbon. These improvements provide a system that is environmentally friendly, with significantly longer life and lower energy consumption. Our patented compression tubes require less than 2m3 of compressed air to produce 1m3 of 95% pure nitrogen. In addition to lower energy consumption, this also means that when using a LOX system, a lower capacity compressor can be used to achieve the desired compressed air volume.

Compared to traditional PSA technology, the HP-PSA offers substantial energy savings. When compared to a membrane system, energy savings of up to 50% can be realized!

Discover the Presscon LOX

Over the past decades, we have worked structurally on the further development of the Presscon Lox “Low Oxygen System” based on our experience.

All our products are developed and assembled in our own factory in Honselersdijk and have developed around our company’s core values of innovation, quality and flexibility.

Because we have in-house production, we are a very flexible organization. This allows us to build to your specific needs and provide a custom installation that meets your requirements, rather than a standard product range. In doing so, we ensure maximum safety of your product or process and significantly reduced running costs. Presscon FX Prevent offers you competitively priced systems with long-term operation and cost-efficient maintenance.

Our goals

We are committed to creating the safest possible environment, working closely with our customers as well as demanding parties such as government and insurers. We can support you in reducing, or in some cases even eliminating, the damage to employees, property or environment caused by fire.